Effective Packaging Cost Strategies for Smarter Business Solutions

- Packaging Lab

- 3 days ago

- 3 min read

Optimizing packaging costs is a critical step for businesses aiming to boost profitability without compromising quality or brand appeal. Packaging is more than just a container; it’s a vital part of your product’s identity and customer experience. Yet, it often represents a significant portion of operational expenses. I’ve explored practical, actionable strategies that can help you reduce packaging costs while enhancing efficiency and sustainability. Let’s dive into these proven methods that can transform your packaging approach.

Understanding Packaging Cost Strategies

Before jumping into cost-cutting measures, it’s essential to understand what drives packaging expenses. Packaging costs include materials, design, production, transportation, and waste management. Each factor offers opportunities for optimization.

Material selection: The choice of materials directly impacts cost and environmental footprint.

Design efficiency: Smart design reduces material use and improves packing density.

Supplier relationships: Negotiating with suppliers can unlock better pricing.

Logistics: Packaging size and weight affect shipping costs.

Sustainability: Eco-friendly packaging can reduce waste disposal fees and appeal to conscious consumers.

By focusing on these areas, you can develop a comprehensive strategy that balances cost, quality, and brand value.

Practical Packaging Cost Strategies to Implement Today

Here are some effective strategies that I recommend for businesses looking to optimize packaging costs:

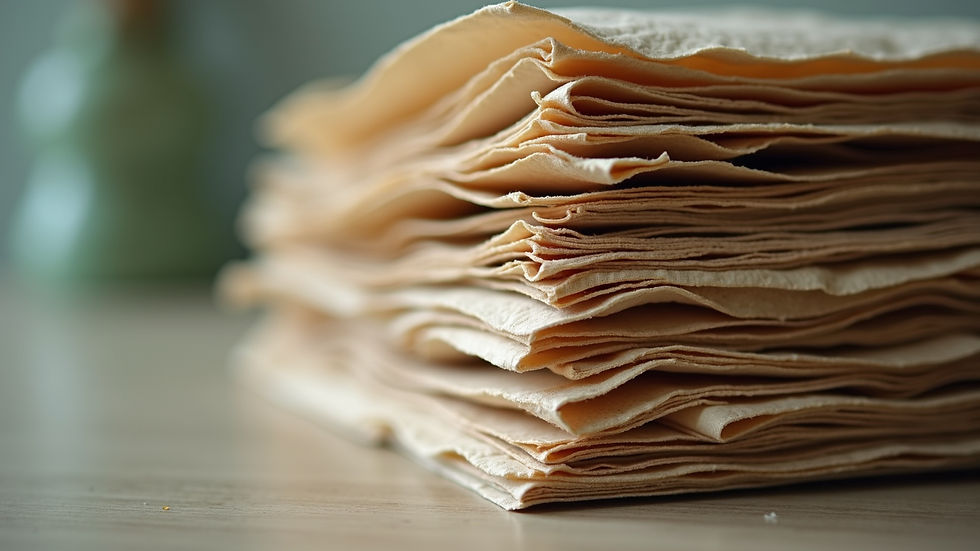

1. Choose the Right Materials

Material costs vary widely. For example, switching from rigid plastic to flexible packaging can reduce material use and shipping weight. Consider recycled or biodegradable materials that may qualify for tax incentives or reduce disposal costs.

Use lightweight materials without sacrificing protection.

Opt for standardized sizes to benefit from bulk purchasing.

Test alternative materials in a packaging lab to ensure durability and cost-effectiveness.

2. Optimize Package Design

Good design minimizes waste and maximizes efficiency. Use software tools or consult packaging experts to create designs that use less material but maintain strength.

Reduce empty space inside packages to lower shipping volume.

Design multi-functional packaging that can serve as display or storage.

Incorporate modular designs for easier stacking and transport.

3. Streamline Supplier and Vendor Management

Building strong relationships with suppliers can lead to better pricing and service.

Negotiate volume discounts or long-term contracts.

Consolidate orders to reduce shipping fees.

Explore local suppliers to cut transportation costs and lead times.

4. Improve Packaging Processes

Automation and process improvements can reduce labor costs and errors.

Invest in machinery that speeds up packaging without compromising quality.

Train staff on efficient packing techniques.

Implement quality control to reduce returns and repackaging.

5. Embrace Sustainability

Sustainable packaging is not just good for the planet; it can also save money.

Use recyclable or compostable materials to reduce landfill fees.

Design for easy disassembly and recycling.

Communicate your sustainability efforts to customers to enhance brand loyalty.

Leveraging Technology and Innovation in Packaging

Technology plays a pivotal role in reducing packaging costs. From digital prototyping to smart packaging, innovation opens new doors.

3D printing allows rapid prototyping to test designs before mass production.

Smart packaging with sensors can reduce product loss and improve supply chain visibility.

Data analytics helps identify inefficiencies in packaging and logistics.

Investing in these technologies can seem costly upfront but often results in significant long-term savings and competitive advantage.

How to Measure and Track Packaging Cost Savings

Implementing strategies is only half the battle. Measuring their impact ensures continuous improvement.

Set clear KPIs such as cost per unit, material waste percentage, and shipping cost per package.

Use software tools to track packaging expenses in real time.

Regularly review supplier performance and packaging quality.

Conduct periodic audits to identify new savings opportunities.

Tracking these metrics helps you stay on course and justify investments in packaging optimization.

Taking the Next Step Toward Smarter Packaging

Optimizing packaging costs is a journey, not a one-time fix. By applying these strategies, you can create packaging that is cost-effective, sustainable, and aligned with your brand’s goals. Partnering with experts, such as those at a packaging lab, can provide valuable insights and customized solutions tailored to your business needs.

Remember, smarter packaging means smarter business. Start small, measure results, and scale your improvements. Your bottom line and the planet will thank you.

Comments